YOUR NEEDS, OUR TOOL.

Our software

Software is essential to analyze the geometry of the tool and its gear. Unfortunately, however, very often they are so complex that they can only be used with the intervention of specialized technicians.

Our software, while analyzing complex geometries, are instead designed to facilitate learning and to be used also by less trained technicians, to the point that they are used by junior technicians for their training.

Among the main software that Global Carbide Tools can design and supply you will find:

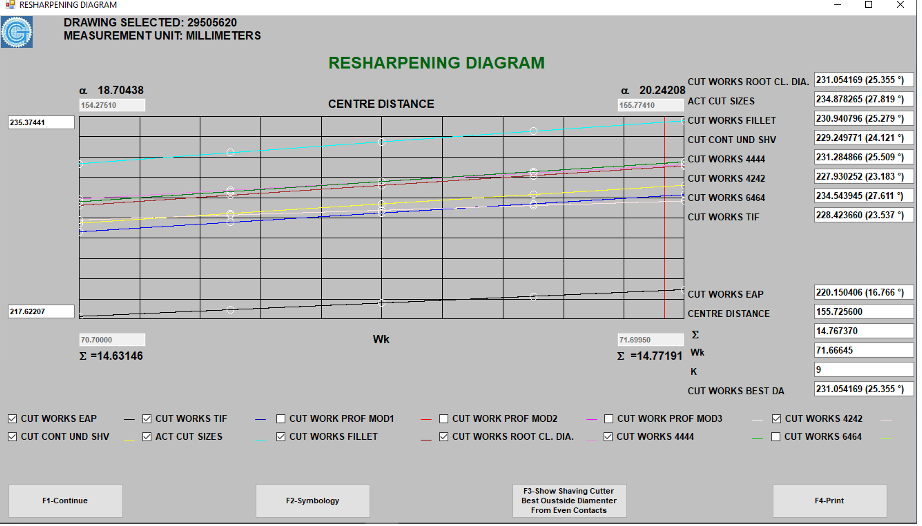

Shaving PROGRAM

- Sharpening diagram calculation and shaving tools design.

- Calculation of even contacts, trend of external shaving diameter, chamfer and undercut diameters, involute TIF and backlash calculation.

- Calculation of gear displacement and shaving cavity.

- Tooth simulation tool with hob and fellows knife to determine the shaving diameters.

- Calculation of root, chamfer and undercut diameters, in hobbing and shaving.

- Calculation of the residual undercut of the toothing (residual undercut) management of semitopping and protuberance.

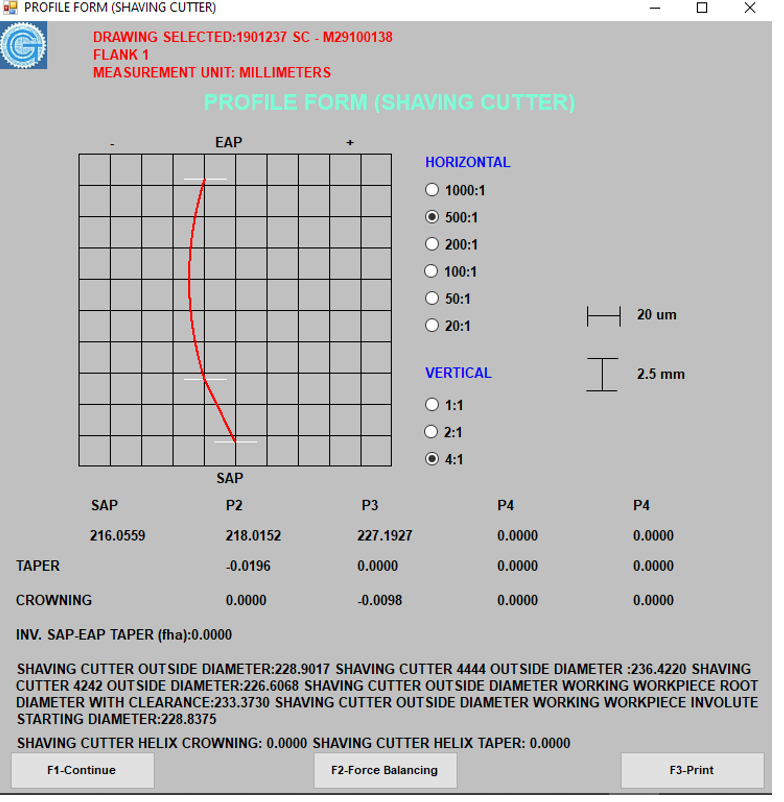

Gear Shaving PROGRAM

- Involute shape calculation and shaving diameters.

- Calculation of the involute shape and of the TIF of the shaver – shaved piece, and vice versa.

- Calculation of even contacts.

- Calculation of the trend of the external diameter and of the backlash.

- Display of the balancing/unbalancing of the shaving forces.

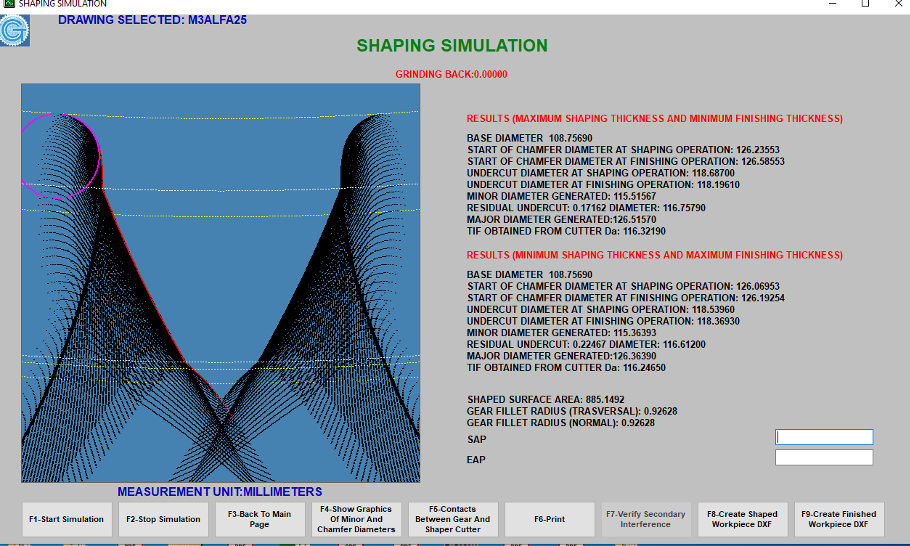

Shaper PROGRAM

- Tooth simulation and fellows knife profile design (for external and internal gears).

- Calculation of the normal rack (Basic rack) equivalent to the fellows knife with tools to determine the knife data present on the drawings of the major manufacturers.

- Analysis with concept of maximum and minimum tooth thickness and finish and vice versa.

- Calculation of the diameter of the gear machined from a cutter diameter and vice versa.

- Calculation of root, chamfer and undercut diameters, in toothing and finishing.

- Calculation of the residual undercut of the tooth (residual undercut) management of semitopping and protuberance.

- Printing of the tooth-finishing profile.

- DXF creation of profiles.

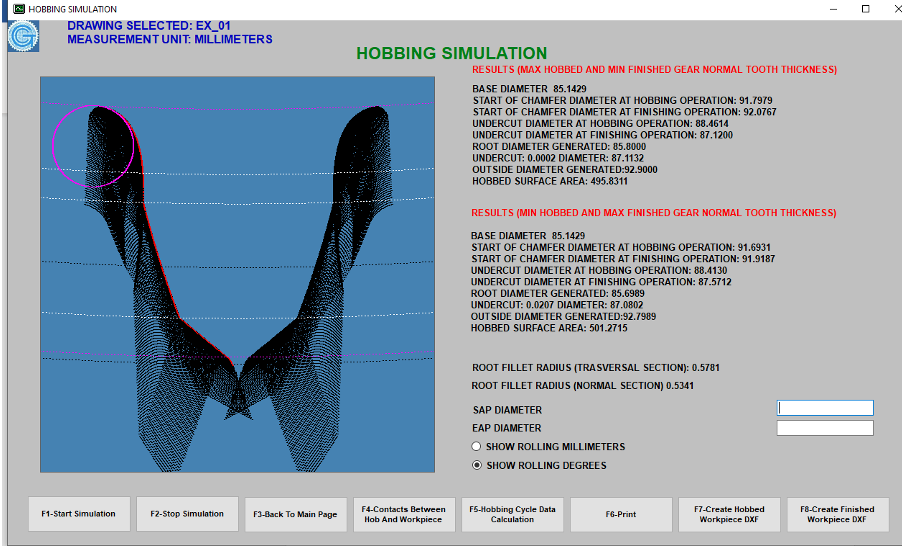

Hob PROGRAM

- Hobbing simulation and hob basic rack design.

- Analysis with concept of maximum and minimum tooth thickness and finish and vice versa.

- Calculation of root, chamfer and undercut diameters, in toothing and finishing; calculation of the residual undercut of the toothing (residual undercut).

- Calculation of the root fillet radius.

- Management of semitopping and protuberance.

- Printing of the tooth-finishing profile.

- DXF creation of profiles.